WONDERBIN Sewage Treatment Plant/Effluent Treatment Plants

WONDERBIN Sewage Treatment Plant/Effluent Treatment Plants

Optimized & Industry-ready Solutions

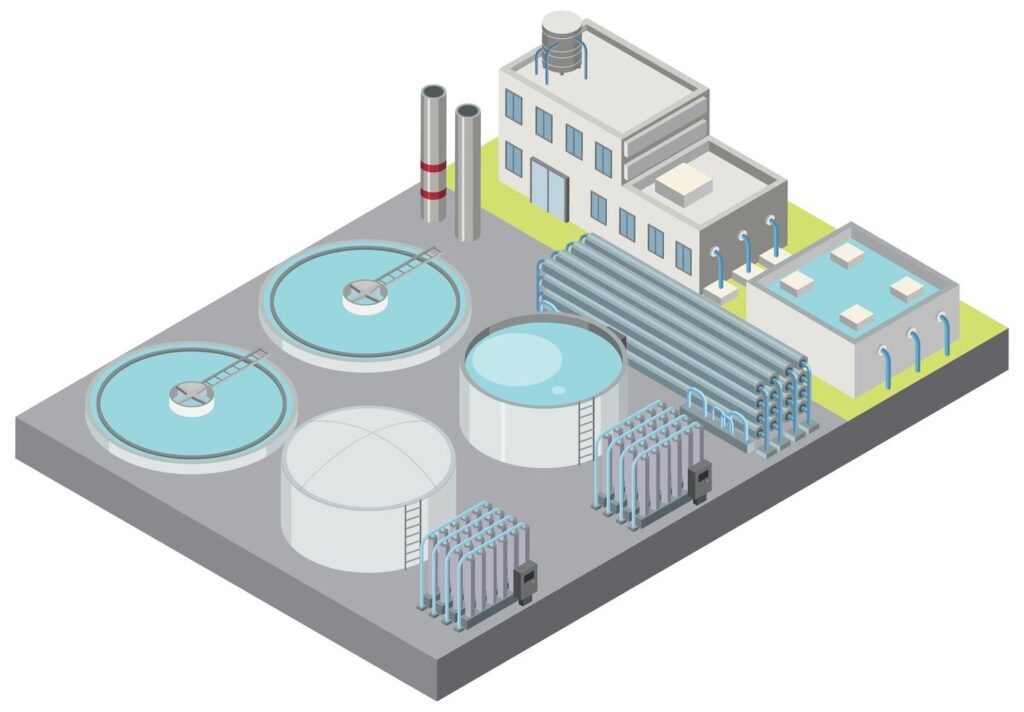

The WONDERBIN Sewage Treatment Plant is a state-of-the-art solution designed for both municipal and industrial wastewater treatment. Engineered to deliver high efficiency and robust performance, this system effectively removes contaminants, pathogens, and suspended solids to produce treated water that complies with strict environmental standards.

Wastewater Treatment

Treating water unfit for human consumption into an effluent that can be returned to the water cycle or reused is an essential step towards maximizing the use of this resource. Synod Bioscience applies its globally recognized technological expertise to extract wastewater’s full value. We help generate reusable water using efficient solutions, implementing water treatment technologies that not only meet stringent quality standards but also reduce ecological impact.

Key Features

Efficient and safe technology

Environmentally compliant sewage plant operations

Minimal ecological impact

Cost-effective and customized solutions

Treatment by-products such as nutrients and fertilizers utilized

Sewage Treatment Plants

Synod Bioscience is the best commercial waste management company that builds and maintains highly energy-efficient and optimized sewage treatment plants. These plants generate lower yields of sludge while maximizing biogas production.

Benefits

i) Highly efficient wastewater treatment

ii) Total nitrogen removal

iii) Minimal odour and noise production

iv) Compliant with safety regulations

v) Less energy consumption with increased biogas production

vi) Cost-effective and easy to operate

1. Conventional ASP Technology

Activated Sludge Process (ASP) is one of the most common suspended growth technologies for municipal wastewater treatment. It includes:

i) Aeration of wastewater in microbial suspension

ii) Solid and liquid separation

iii) Clarified effluent is discharged

iv) Excess biomass is wasted

v) Remaining biomass is returned to the aeration tank

2. Sequential Batch Reactor (SBR Technology)

This activated sludge process treats wastewater through various time-based stages in a single tank. Synod Bioscience installs SBR systems using pumps, mixers, aerators, and decanters controlled by programmable logic controllers monitored by our team.

3. Moving Bed Bio Reactor (MBBR)

An economical and highly efficient method for both municipal and industrial wastewater treatment. MBBR is used for removing organic substances, nitrification, and denitrification with low energy consumption.

Effluent Treatment Plants (ETPs)

Synod Bioscience provides customized effluent treatment solutions tailored for industries and municipalities. Our systems ensure consistent efficiency and regulatory compliance.

Process Steps

Screening Chamber: Removes floating debris and grit

Oil & Grease Trap: Eliminates floating oil from raw effluents

Primary Treatment: Coagulation, flocculation, and neutralisation; removes suspended particles

Secondary Treatment:

Aerobic: ASP, MBBR/FAB, MBR

Anaerobic: UASB (Up-flow Anaerobic Sludge Blanket Reactor)

Tertiary Treatment: Sand & carbon filtration, reverse osmosis, ultrafiltration

We provide turnkey solutions for the design, manufacture, and installation of sewage and effluent treatment plants. Our plants are used by government bodies, industries, and large establishments and are fully customizable to meet area and waste requirements.

Product Features

Advanced Multi-Stage Treatment

Incorporates primary, secondary, and tertiary treatment processes—including physical separation, biological degradation, and chemical disinfection—to ensure thorough removal of impurities.

Modular & Scalable Design

Customizable to handle varying volumes of sewage and effluent, making it ideal for small communities, large institutions, and industrial facilities.

Automated Monitoring & Control

Equipped with modern SCADA systems and real-time sensors, the plant continuously monitors critical parameters such as flow rate, pH, and dissolved oxygen. This automation ensures optimal performance and rapid response to any fluctuations.

Energy & Cost Efficient

Designed to minimize energy consumption and reduce operating costs, the system’s efficient process design leads to lower maintenance needs and long-term savings.

Robust Construction

Built using high-grade, corrosion-resistant materials to withstand harsh operating environments and ensure a long service life with minimal downtime.

Environmentally Friendly

By effectively reducing harmful discharges, the WONDERBIN plant supports sustainable water management and helps organizations meet regulatory compliance and environmental responsibility goals.

How It Works?

Pre-Treatment

Wastewater enters the plant where large solids and grit are removed through screening and sedimentation.

Primary Treatment

Settling tanks allow suspended solids to settle out, forming a sludge that is then processed separately.

Secondary Treatment

Biological processes break down organic matter using microbial activity in aeration tanks, further reducing pollutants.

Tertiary Treatment & Disinfection

Advanced filtration and chemical or UV disinfection remove remaining contaminants and pathogens, ensuring high-quality effluent.

Sludge Management

The separated sludge is treated further, often through digestion or dewatering, to produce usable byproducts such as biogas or fertilizer.